Scope

In 2015, the Company decided to invest in a massive component handling system from Eton Systems; the goal was to eliminate some of the required component knowledge and manual labor for mattress assembly.

My job was to ensure this system could communicate with their newly deployed ERP that held raw material and work-in-progress information for each SKU. The project required communication between; us, the machine's supplier, and our ERP system's developers. In addition, our scheduling, mattress assembly departments, and maintenance crew would regularly interact with the system (around 30 users).

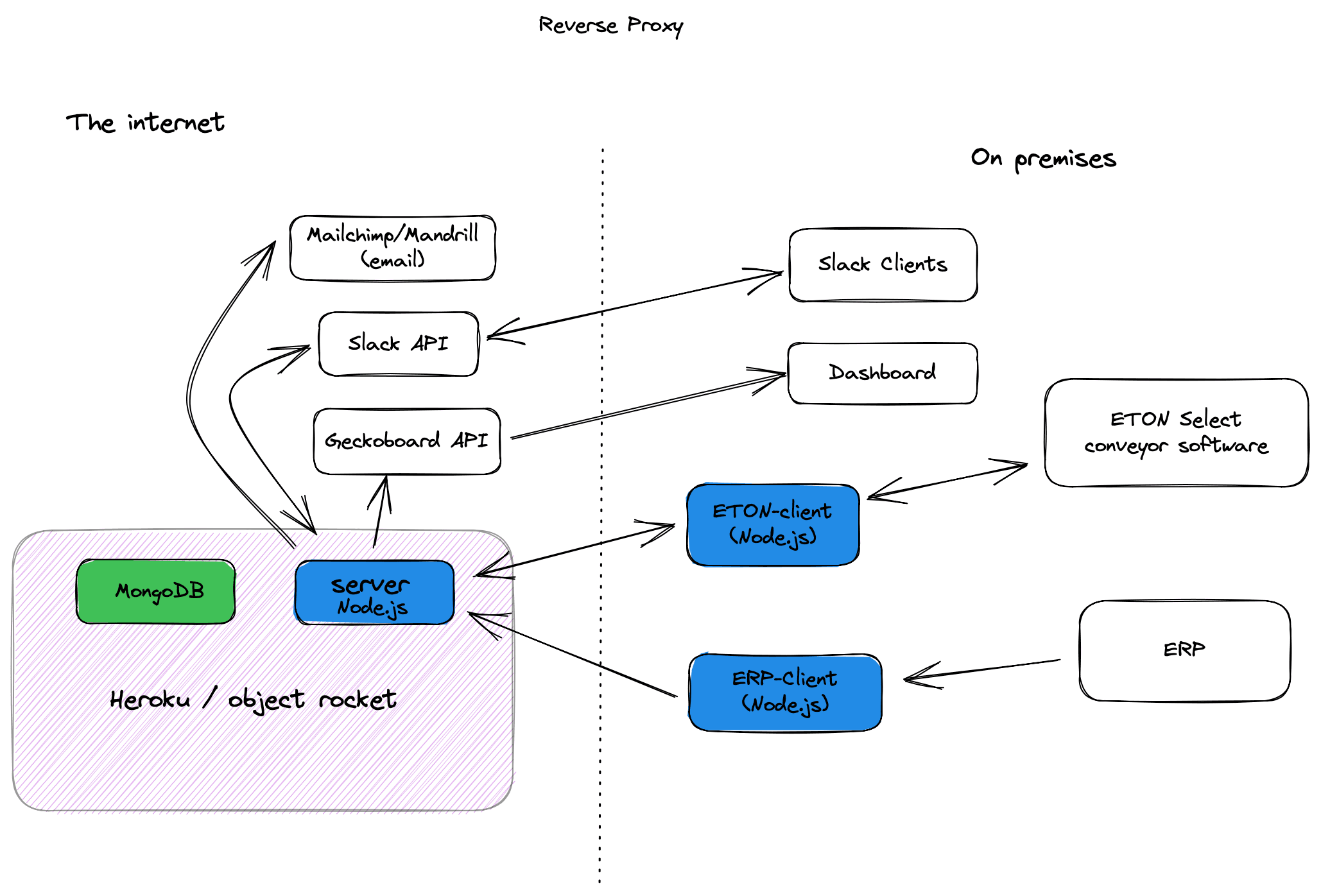

After visiting other installations & finalizing the scope of work, I had to write the middleware for the two systems. To avoid general hardware and network issues, I decided to deploy most of the service on the internet; I had no experience doing this and took a chance using Heroku. I felt it would be more accessible than configuring a hosted Docker or EC2 instance on AWS.

Slack

At this time, many factory employees owned cell phones and communicated via WhatsApp; I knew that fast and efficient communication on issues would be handy when introducing this system; most importantly, I had no resources for front-end or user interaction.

So, I decided to use Slack for everything.

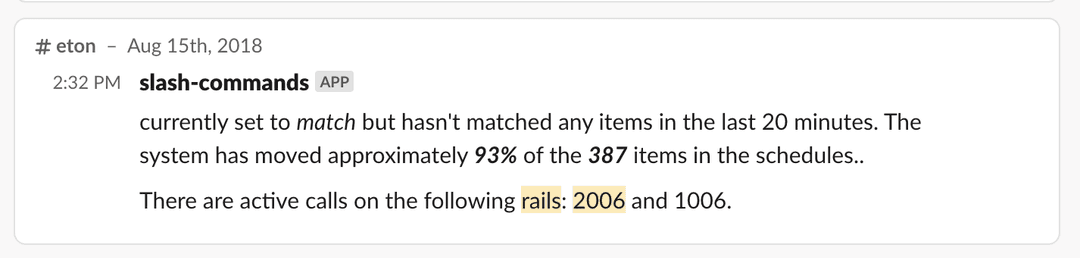

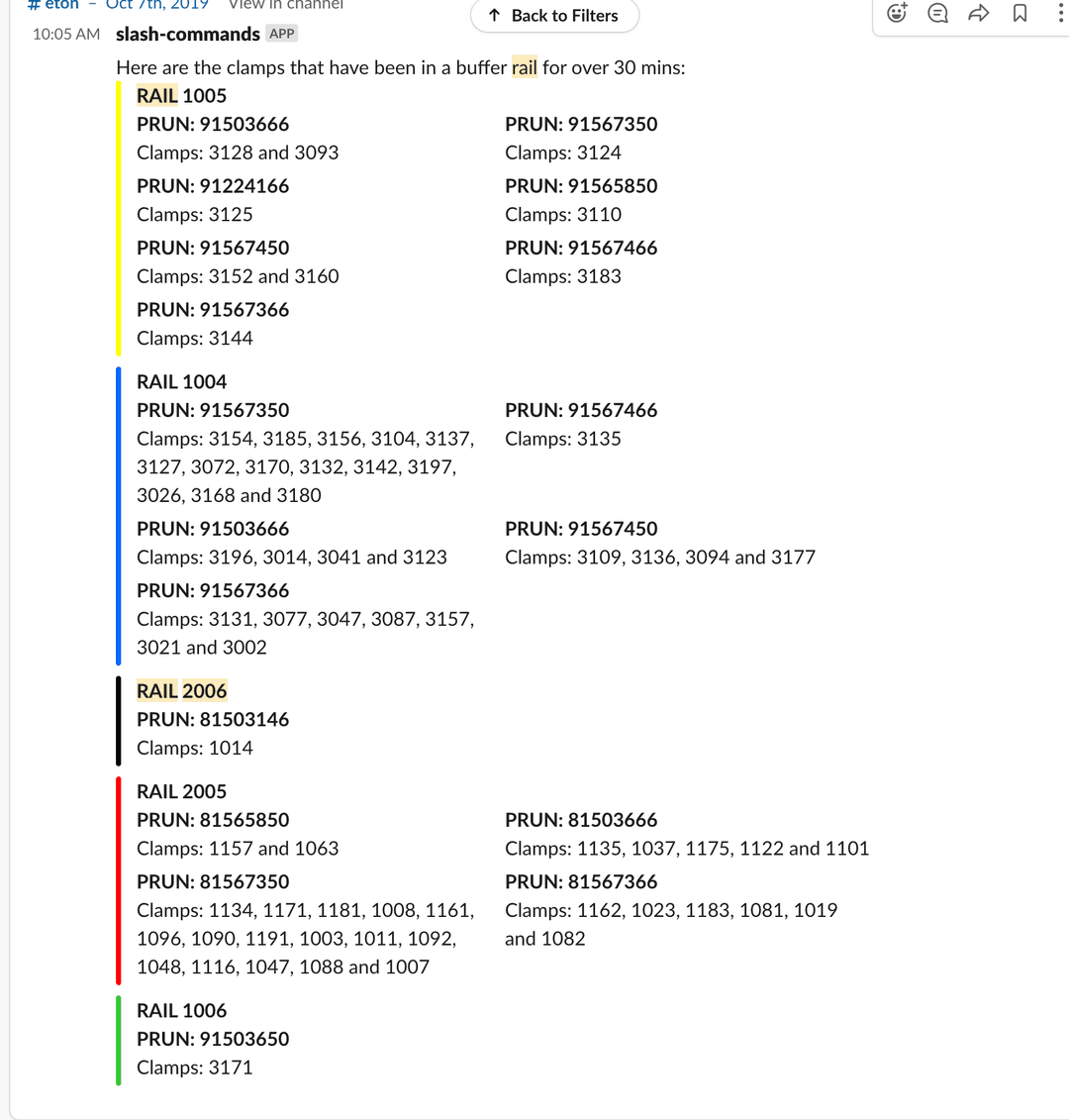

Some of the output below:

If someone had an issue, they could query or instruct the system using slash commands. The output was there for everyone to see and provided a starting point for discussing facts over anecdotes. It also gave insight into how employees generally used the system.

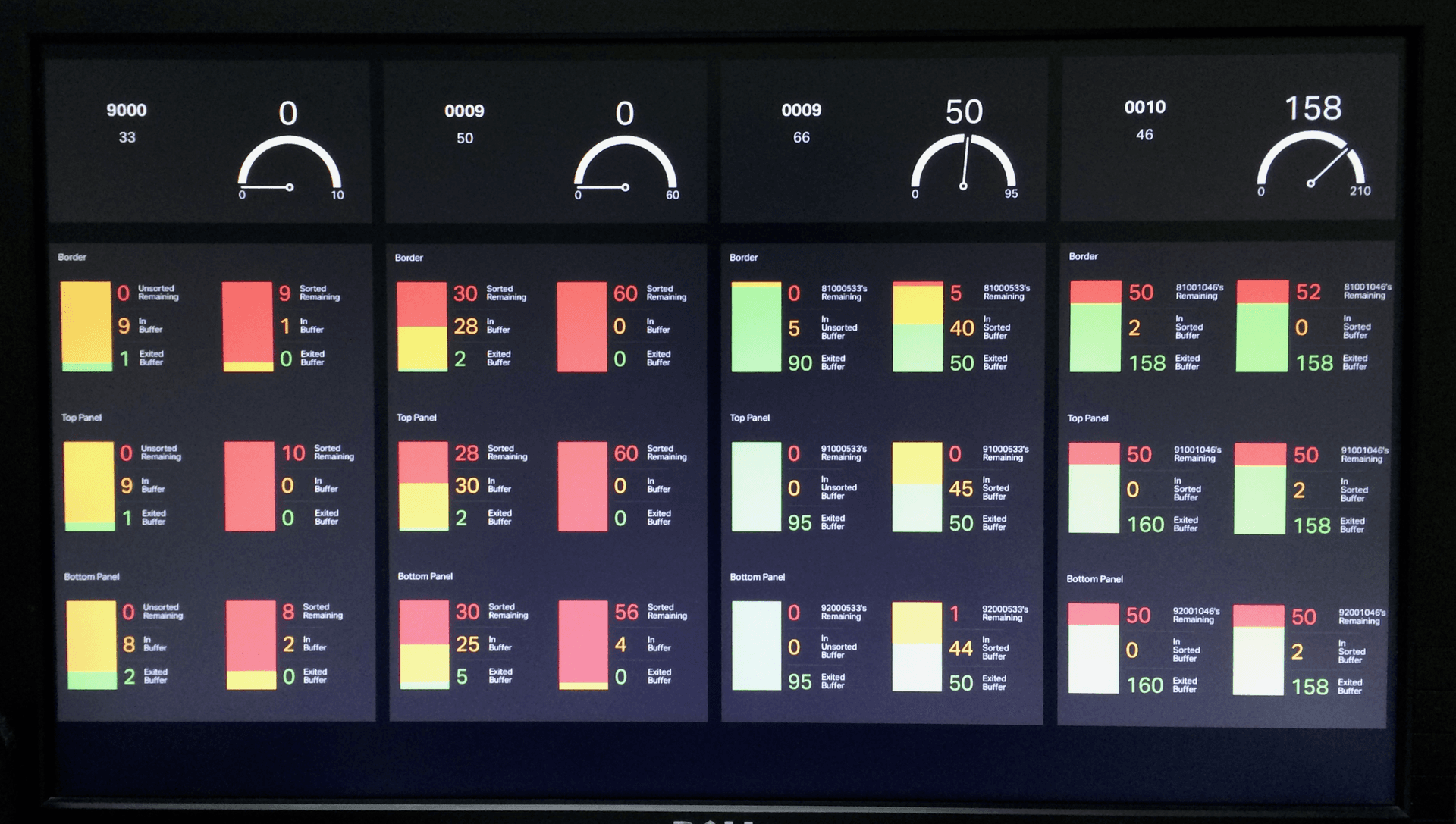

We had a mixed launch. Our managers and factory workers appreciated the reduced labor, better reporting, and structured workflow. A few months later, I introduced a dashboard using Geckoboard, which was displayed across three large displays on the factory floor. Roughly 80% of all fabric components for the mattresses would traverse the system for the next two to three years.

Here's what one of the three Geckoboard dashboards looked like:

A recurring complaint was that the system introduced extra lag at the beginning of a workday that needed to be remediated by workers arriving early to load components onto it. After much deliberation, upper management decided to disallow components from being loaded onto the system any earlier than the day they were needed; the decision discouraged managers from using the machine during COVID, and usage steadily fell over time.